Shopping

Art Glass, Tools & Supplies Est. 1984

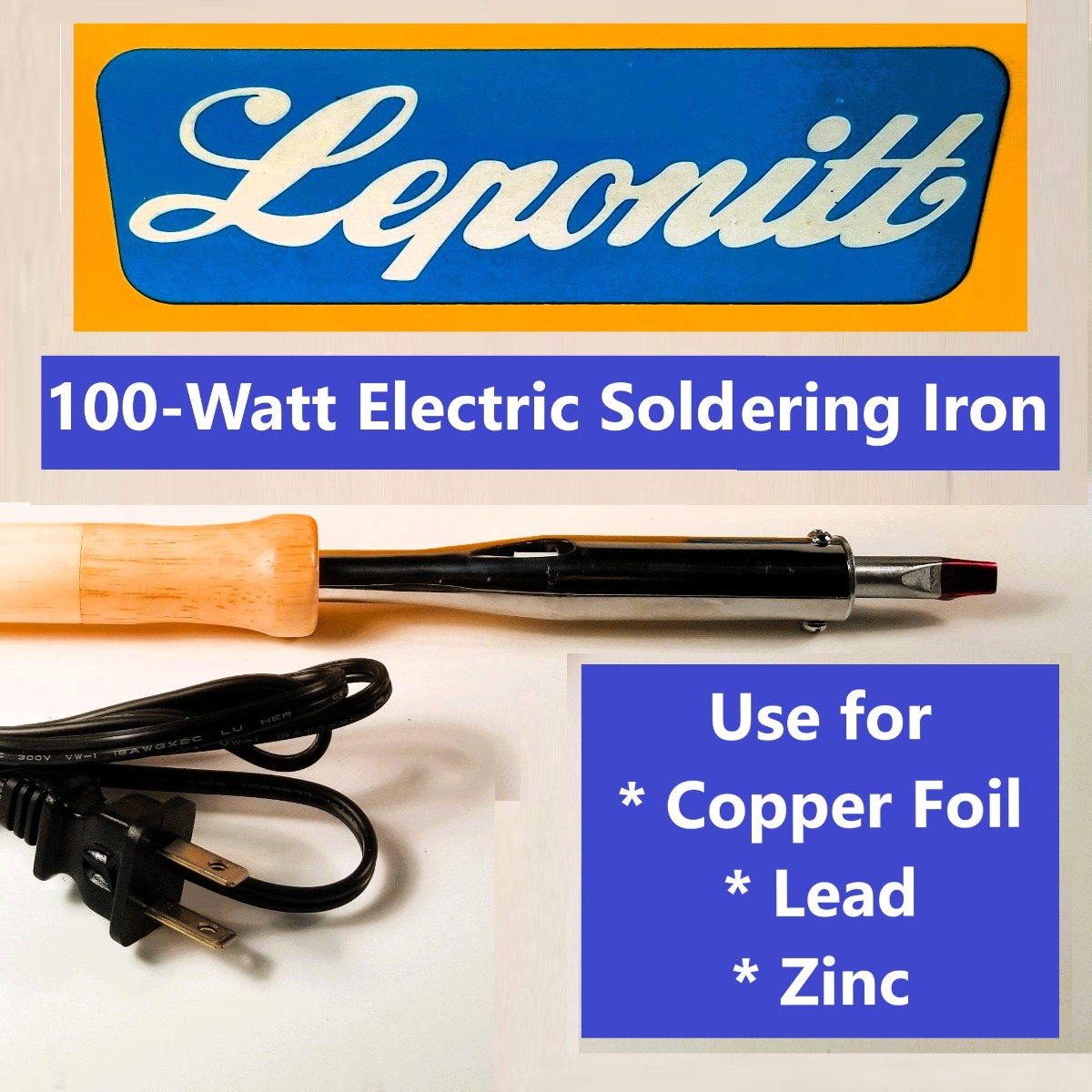

Leponitt 100 Watt Soldering Iron

Leponitt Electric Soldering Iron 100 watts, 110 volts

The Leponitt brand soldering iron is an excellent selection for usability and value. Use for stained glass copper foil work, lead or zinc. Great for Hobbyists and students.

It is important to know this iron is not temperature-controlled. For best performance and product longevity, this soldering iron should be connected to a rheostat device that changes and controls the flow of electrical current.

More expensive soldering irons have the rheostat device built into the handle.

The Leponitt soldering iron can be operated without the rheostat. Extra care is needed to ensure acceptable results.

Features

- 100 Watt, 110 Volt soldering iron

- Not temperature controlled.

- Use for copper foil, lead or zinc.

- 5/16-inch (7.94 mm) zinc-plated tip (no other sizes available)

- Red Plastic tip protection melts off

- Medium size-grip wood handle

- Stainless steel vented barrel

- 11-1/2 inches (29.2 cm) long

- Cord: 55 inches (139.7 cm) long

- Two-pronged Type A electrical plug

- Weight: 7 ounces (198.5 grams)

- Warranty 6 months.

- Electrical device. Handle with Care.

- Heat-up time to melt solder: approximately 2 minutes.

- Caution: tip temperature can exceed 700 degrees Fahrenheit.

For best performance, this iron should be connected to a rheostat device.

If using without a rheostat, follow these tips: Heat soldering iron only for when in use. Limit soldering time to avoid overheating. Overheating the soldering iron can stop it from working.

With most electric soldering irons the handle will feel warm from the heated barrel. If the handle becomes hot, unplug your iron and let it cool.

Soldering iron tips will collect impurities from the solder and flux so tip maintenance is required. While soldering, regularly wipe the tip on a damp sponge.

The inevitable impurity build-up will decrease the effectiveness of the soldering iron tip where the solder does not liquefy.

The iron tip can be kept at peak performance by regularly treating the soldering iron tip with Sal Ammoniac.